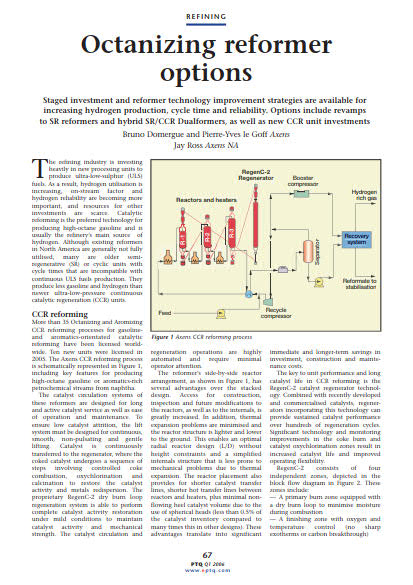

The refining industry is investing heavily in new processing units to produce ultra-low-sulphur (ULS) fuels. As a result, hydrogen utilisation is increasing, on-stream factor and hydrogen reliability are becoming more important, and resources for other investments are scarce. Catalytic reforming is the preferred technology for producing high-octane gasoline and is usually the refinery’s main source of hydrogen.