New and revamped refining complexes are meeting the new clean fuels and shifting product requirements challenge with the help of new process technologies. The flexible, low cost FCC refinery conversion unit is adapting to play a role as a clean petrochemicals producer to help close a widening gap between propylene supply and demand. Axens has developed and commercially demonstrated a new riser separation system to attain high product containment for maximum yield selectivity.

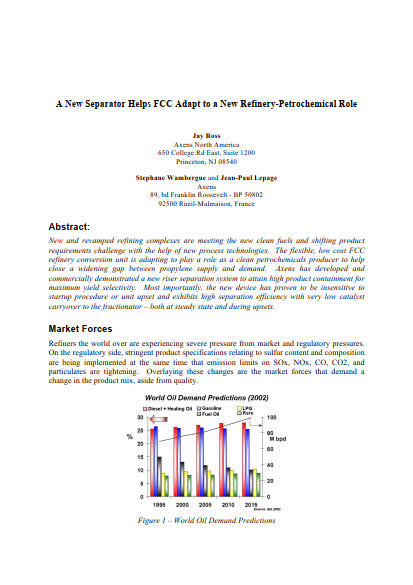

Most importantly, the new device has proven to be insensitive to startup procedure or unit upset and exhibits high separation efficiency with very low catalyst carryover to the fractionator – both at steady state and during upsets.