Bio Olefins

The chemical industry needs to address challenges related to circular economy and society growing demand for more sustainable products and lower industrial carbon footprint.

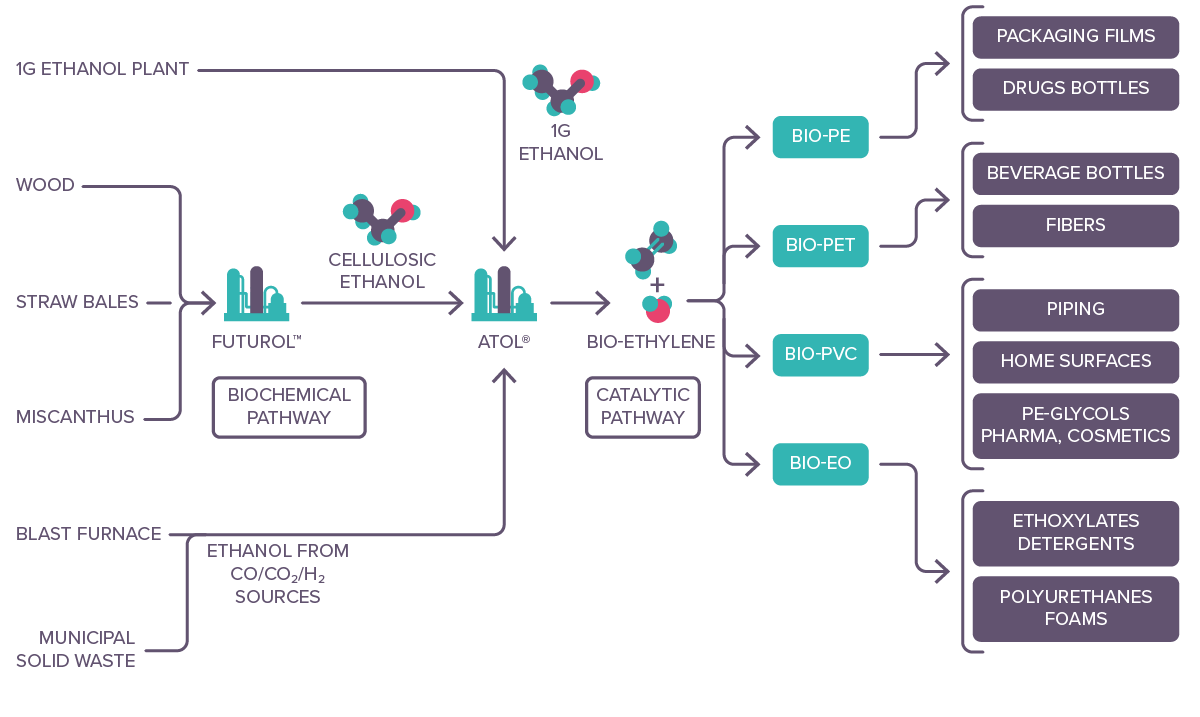

Bio-based chemicals open the door to green value chains for chemicals and polymers with high attractiveness that can certainly help overcome these challenges. In this realm, Axens provides technologies to convert renewable alcohols into olefins, which are a key compound for the chemical industry.

Ethylene is one of the most important building blocks of the chemicals industry and can be produced either via traditional fossil pathways or from renewable feedstocks.

Atol® technology proposes the most promising green route via catalytic dehydration of renewable ethanol. The production of bio-ethylene from a large panel of ethanol feedstocks is now at hand. The quality of the bio-ethylene of Atol® makes it possible to tap into a wide range of applications.

As illustrated below, with Atol® technology, the production of bio-ethylene from a large panel of ethanol feedstocks is now at hand. The quality of the bio-ethylene of Atol® makes it possible to tap into a wide range of applications:

Atol® technology is also meant to bring into the market a soft solution to help the chemical industry upgrading the production assets by utilizing drop-in products that can be processed directly in the current assets.

Butadiene is a key chemical intermediate that is used to produce synthetic rubber, the raw material for a large variety of products of the daily life. About 60% of rubber worldwide production is dedicated for the tire manufacturing industry, which represents a huge potential market.

Moreover, the rubber industry has suffered over the past years from butadiene supply shortages caused by new investments in low-cost gas steam crackers.

Events

All eventsContact Us

Please fill in the form below to get in touch with us