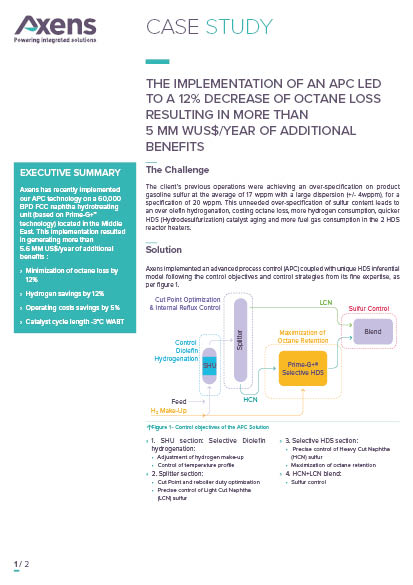

To what extent do you see the expansion of digitalization for improving regulatory compliance, equipment reliability and operability, and reduced maintenance costs?

Digital Applications - Innovative approach leveraging digital solutions leading to improved asset operation and performance.

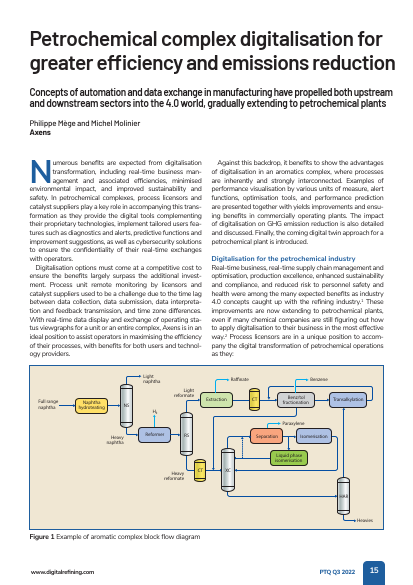

Learn moreDigitalization of process operations has developed thanks to data transfer technologies, sensors and soft sensors generating data, and IA, especially with machine learning tools, building systems that learn from data. This leverages process expertise, resulting in digital twins designed to optimize asset operation, thus securing the business decision.

That ensures reliable operation and allows us to anticipate maintenance, which reduces its cost, and compare actual performances vs forecasted ones. This applies to catalysts and also equipment like heaters, compressors, and heat exchangers.

Such tools are available in the Axens Connect’In® digital application. Several machine learning tools have already been developed and used by operators for octane prediction, recycle gas purity estimation, heat exchanger network optimization, or generating soft sensors to get streams analysis not directly measured.