CEED™ Studies can be performed at the beginning of the basic engineering stage.

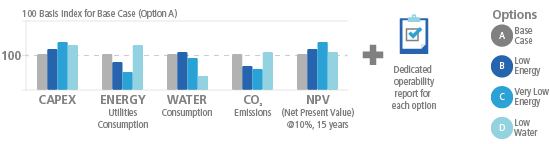

The customer selects a set of criteria representing its specific priorities and constraints, for instance energy efficiency, CO2 emissions, or water footprint. Axens then works with them to conduct a study, enabling several options to be elaborated and evaluated, all tailor-made to meet operators’ needs.

Early Design

A CEED™ study deliverable is a powerful customer decision-support tool. Indeed it ensures that the selected scheme is based on a solid foundation optimizing both the project’s environmental impact and economics.

The basic engineering design phase is the best moment for an operator to optimize the use of every resource. Regarding energy efficiency, in addition to PINCH analysis, which is commonly used in the industry, CEED™ studies rely on in-house tools developed with IFP Energies nouvelles. Innovative equipment can also significantly reduce the project’s environmental footprint (lower energy and/or water consumption, etc.), that’s why CEED™ studies involve our team of equipment specialists and our extensive network of equipment manufacturers.

Within a short period of time, CEED™ studies required in-depth exchanges with site operator teams in order to provide the best customized solutions. These interactions have a very low impact on basic design engineering schedules. Above all, as a technology licensor, Axens ensures that the proposed optimal scheme is robust and safe considering all the flexibility needs such as various operating modes, start-up needs and specific catalyst treatment steps. Therefore additional scrutiny by another layer of experts is not warranted, potentially saving our clients significant cost and schedule impacts.

TO CONTACT US

Please fill in the contact form below