First published in PTQ Q1 2021

Gregory Lapisardi, Technologist, Middle distillates HDT, Axens

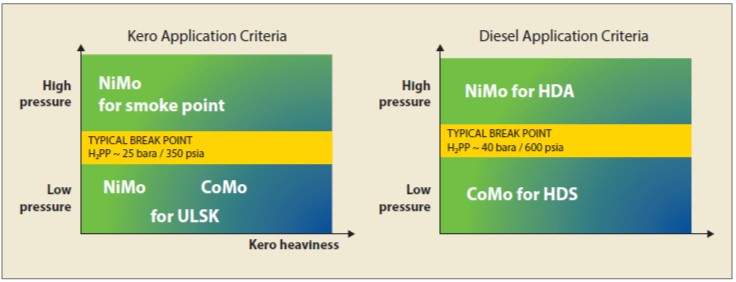

When it comes to selecting the right catalyst for the hydrotreatment of a middle distillates fraction at low pressure, a distinction has to be made between light (kerosene) and heavy (diesel) cuts.

In a low pressure kerosene hydrotreater, nickel-molybdenum (NiMo) catalysts are in most cases the best choice. When the heaviness of the feed is increasing toward a light diesel cut, a cobalt-molybdenum (CoMo) catalyst can also be considered (see the Figure on the left).

Low to medium pressure diesel hydrotreaters are the playground of CoMo catalysts. Thanks to a higher selectivity towards hydrodesulphurisation reaction, in comparison with a NiMo catalyst, a CoMo catalyst will exhibit a higher hydrodesulphurisation rate for a limited hydrogen consumption.

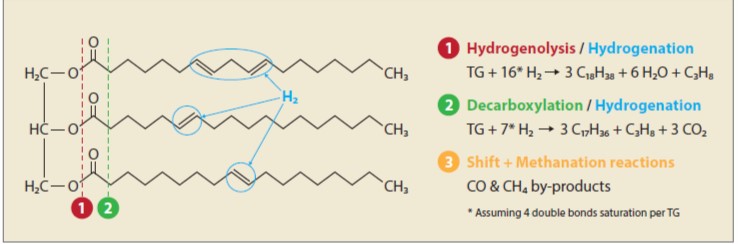

However, the latest challenges appearing in refineries are questioning the domination of CoMo catalysts in low to medium pressure diesel hydrotreaters. Co-processing of lipids (vegetable oils, animal fats, UCO…) is one of them. Renewable feedstocks, like vegetable oils, are mainly composed of triglycerides as well as glycerides and free fatty acids.

The desired reaction for converting vegetable oils to commercial fuel is the deoxygenation of these molecules in the presence of hydrogen to form linear paraffins, propane, CO2, and water (see the Figure on the left). The water gas shift equilibrium will lead to the presence of carbon monoxide in the recycle gas. The higher the incorporation rate of vegetable oil, the higher will be the concentration of carbon monoxide in the recycle gas.

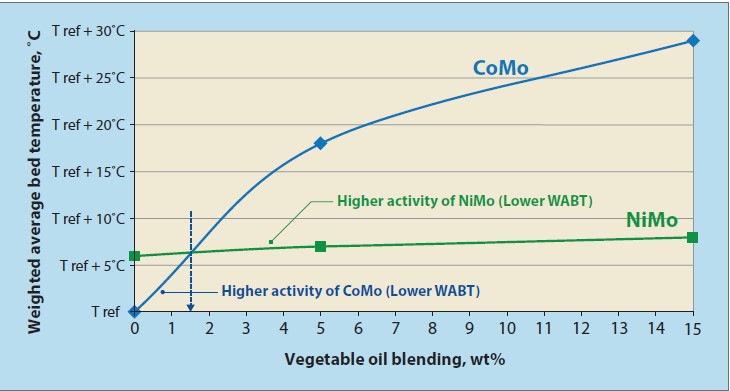

CoMo catalysts are strongly inhibited by carbon monoxide partial pressure while inhibition for NiMo catalyst is very limited. For this particular case, in a low pressure unit, it is recommended to load NiMo catalysts or at least a stack bed of NiMo/CoMo catalysts when the unit has hydrogen availability constraints (see the Figure on the left).

Get the latest news about Proven Solutions in Oil Refining

Subscribe to our business newsletter to keep up to date with Axens news.

This newsletter gives access to our experts' insights and the opportunity to stay up-to-date with our latest products, technologies and services.