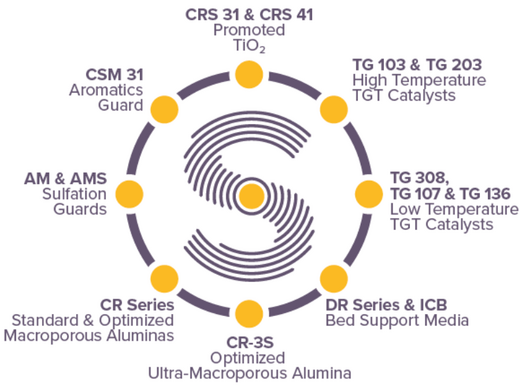

Axens offers dedicated products for hydrogenation process where sulfur species are reduced back to H2S and recycled to the Claus section inlet. SulShine® optimized catalysts help reaching the ever-increasing stringent specification on sulfur emissions from the gas plant or refinery.

Axens special catalysts combine excellent activity for the hydrolysis and hydrogenation of Sx, SO2, COS and CS2 with CO-shift conversion.

Conventional Temperature Operation

Conventional Temperature Operation

These catalysts, with high surface area, optimized pore structures and metal content, exhibit very high stability and crush strength.

Low Temperature Operation

Low Temperature Operation

Reducing the inlet temperature to the hydrogenation reactor allows savings on the cost of fuel to fire these units. Maintaining high TGTU performance while lowering reaction temperatures requires extremely active catalysts. Axens’ high activity catalysts will allow reducing inlet temperatures below 220°C with no loss in performance.

Resources

You Might Be Interested In

Claus Catalysts

TO CONTACT US

Please fill in the contact form below