Hydrocracking Catalysts

As hydrocracking catalyst technologies evolve, an incremental advance in catalyst selectivity, activity, and stability can transform refinery economics, Axens delivers high-performance hydrocracking catalysts designed to unlock value from the most challenging feeds. Our solutions empower refiners to maximize flexibility, extend cycle life, and achieve targeted product yields—while meeting today’s demanding operational and sustainability goals.

Synergy of Impulse® hydrotreating catalysts with Craken® hydrocracking catalysts enables the refiners to achieve the highest level of performance.

Driven by the growing R&D and real-world experience, Axens hydrocracking catalysts have helped refineries process opportunity crudes, co-process renewable feedstocks, and optimize product slates. Our innovations drive operational efficiency and support the transition to more sustainable refining.

Superior Activity, Selectivity & Stability

Premium Performance

A high-activity hydrocracking catalyst designed to deliver premium performance across the cycle and maximize unit profitability.

Targeted Selectivity

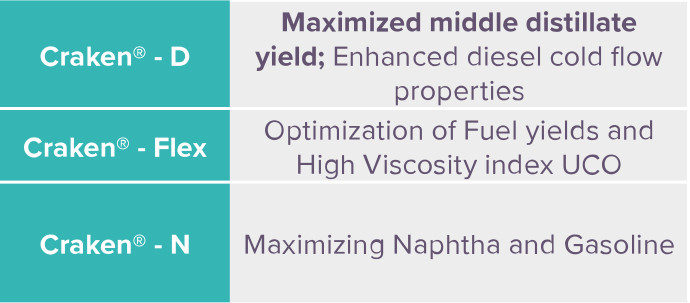

Catalyst solutions engineered to maximize production of high-value streams as required by the Refiner

Maximizing Cycle Length

High stability minimizes deactivation of the catalyst, maximizes cycle length and maintains steady performance across the entire cycle.

Enhancing Operational Flexibility

High nitrogen tolerance expands feedstock flexibility, enabling processing of refractory feeds while maintaining hydrocracking unit performance, thereby maximizing unit’s profitability.

Hydrocracking Feed Pretreatments

Hydrocracking

Resources

Technical Article - Hydroprocessing and Hydrocracking DAO

Technical Article - High Conversion Hydrocracking Catalysts

Technical Article - Upgrade Vacuum Residues And Other Hard-to-Convert Heavy Ends To Get More ULSD Through Hydrocracking Solutions

Technical Article - Hydrocracking Solutions Squeeze More ULSD From Heavy Ends

Technical Article - Upgrade Vacuum Residues And Other Hard-to-Convert Heavy Ends To Get More ULSD Through Hydrocracking Solutions

Technical Article - Hydroprocessing and Hydrocracking DAO

Technical Article - Hydrocracking Solutions Squeeze More ULSD From Heavy Ends

Technical Article - High Conversion Hydrocracking Catalysts

Successful startup of Axens’ Residue Hydrocracking Unit and High Conversion Hydrocracking Unit at Shenghong’s Integrated Refinery Axens 渣油加氢裂化及高转化率加氢裂化装置在盛虹炼化一体化项目中 成功投产

Axens’ recent Successes in Hydrocracking

Axens Awarded complete Residue Hydrocracking solution towards naphtha production for Shenghong

Craken™: Axens’ New Generation of High Performance Hydrocracking Catalysts

You Might Be Interested In

Reactor Internals

Gums & Polymer formation control

Speciality Bed Topping

TO CONTACT US

Please fill in the contact form below