Axens Offer

To respond to the market, Axens has strengthened its offer in etherification solutions offering several schemes that are very versatile and can be tuned to reach the following objectives:

- Moderate to very high conversion while minimizing the formation of by-products

- Staged investment

- Possible switches between methanol and ethanol

- Possible processing of C4s and C5s

Explore some

Resources

Insight

Maximizing the Production and the Transformation of Aromatics

Insight

Targeting the Highly Coveted Olefins

Insight

Two Conversion Routes to Maximize the Economic Returns of a Crude-to-Chemicals Project

Insight

Recommended Process Routes for Maximized Oil Conversion to Aromatics and Olefins

Insight

Maximizing the Production and the Transformation of Aromatics

Insight

Targeting the Highly Coveted Olefins

Insight

Two Conversion Routes to Maximize the Economic Returns of a Crude-to-Chemicals Project

Insight

Recommended Process Routes for Maximized Oil Conversion to Aromatics and Olefins

Whitepaper

White Paper - Crude-to-Chemicals

Press release

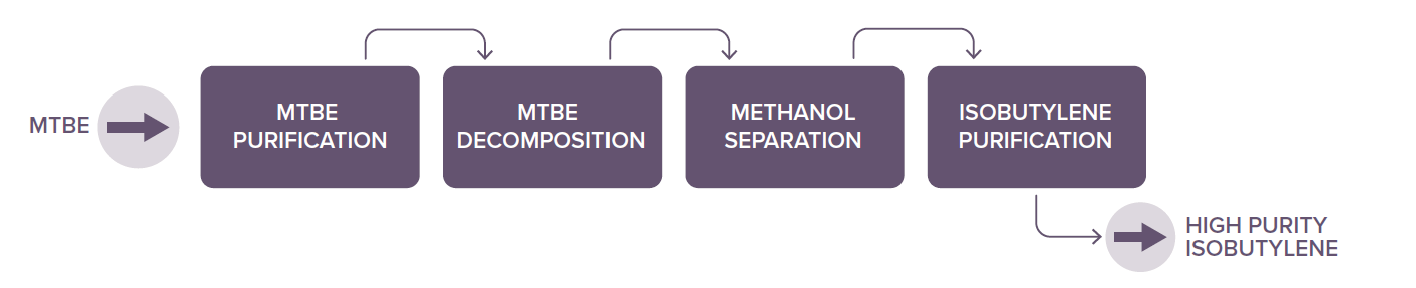

Axens builds on ExxonMobil MTBE Decomposition Technology for high purity isobutylene production

Press release

Axens is awarded a licensing contract for Borouge 4 project in UAE

Press release

Taiwan-Japan Oxo Chemical Industries Inc. Selects Axens’ Technologies for an Isononyl Alcohol production plant in Kaoshing area, Taiwan

Press release

Axens to supply technologies for S-OIL’s residue upgrading capacity expansion project

TO CONTACT US

Please fill in the contact form below