- Combines ExxonMobil’s operating experience with Axens’ licensing and engineering expertise

- Includes standalone FLEXICOKING technology license option or in combination with Axens’ H-Oil Process

- Ideal option to meet IMO 2020 standards and eliminate high-sulfur fuel oil

- Clean burning flexigas by-product replaces liquefied petroleum gas or liquefied natural gas while substantially minimalizing pet-coke

- FLEXICOKING is the leading option to co-produce power, offering 40% lower capital investment versus pet-coke gasification-based solutions

ExxonMobil (Houston – Texas) announced that ExxonMobil catalysts and Licensing LLC and Axens have signed a licensing alliance agreement to allow Axens to provide ExxonMobil’s FLEXICOKING™ technology and integrated resid conversion solutions.

Under the agreement, Axens is granted a worldwide right to market, license and provide engineering work and technical support for the design, construction and start-up of new FLEXICOKING units. The technology will be offered under a single license and engineering agreement to be provided by Axens. This new alliance leverages collective expertise to meet customer needs by providing a resid conversion solution that maximizes liquid yields and minimizes pet-coke production.

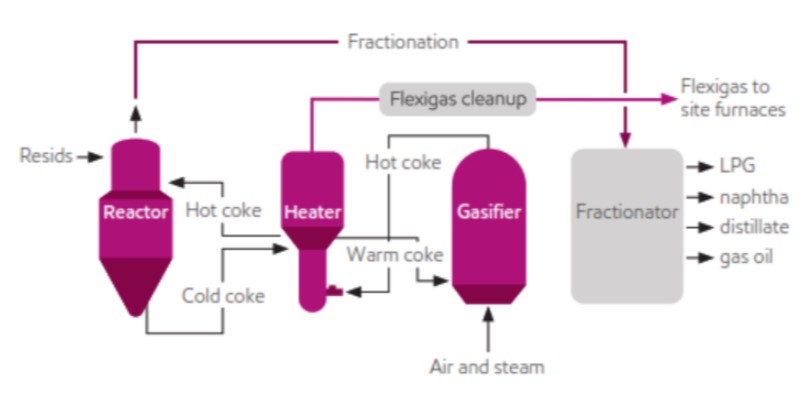

FLEXICOKING technology is a commercially proven, cost-effective, continuous fluidized bed process that thermally converts heavy feeds to lighter products and flexigas. FLEXICOKING technology, when integrated with Axens H-Oil technology, offers flexibility when upgrading residuum. It provides smart solutions that enhance high-value liquid products as well as clean flexigas that can be used as fuel substitute or for power generation, making it an ideal option to meet IMO 2020 fuel standards. When configured for power generation, it offers 40% lower capital investment vs. a delayed coker combined with pet-coke gasification.

We are excited to expand our partnership with Axens and provide this proven technology to the industry. In particular, FLEXICOKING offers a robust, capital and energy efficient process compared to installing a delayed coker unit and an independent gasifier complex for power or fuel gas production.By combining our owner-operator experience with Axens’ strong licensing and engineering expertise, we are able to provide advanced technologies to help meet refinery and crude to chemical-complex customer needs.

We are pleased to once again partner with ExxonMobil to better meet client needs to address terminal residue conversion while producing less coke or low-value blendstock. The alliance brings a combination of FLEXICOKING and H-Oil technologies to provide a compelling new resid conversion option to our customers.

FLEXICOKING technology services include:

- Initial consultation

- Development of licensing proposal

- Basic engineering package, including design specification and operating guide

- Engineering support during front-end engineering and design and engineering, procurement and construction stages

- Technology transfer, training and startup support

- Unit monitoring services for ongoing optimization

The FLEXICOKING process:

Find out more about the FLEXICOKING Technology.

About ExxonMobil Catalysts and Licensing LLC

ExxonMobil’s cutting-edge process technologies help refineries and petrochemical manufacturers and gas processors increase capacity, lower costs, improve margins, reduce emissions and operate safe, reliable and efficient facilities. For more information View the video

About Axens

Axens (www.axens.net) is a group providing a complete range of solutions for the conversion of oil and biomass to cleaner fuels, the production and purification of major petrochemical intermediates as well as all of natural gas' treatment and conversion options. The offer includes technologies, equipment, furnaces, modular units, catalysts, adsorbents and related services. Axens is ideally positioned to cover the entire value chain, from feasibility study to unit start-up and follow-up throughout the entire unit cycle life. This unique position ensures the highest level of performance with a reduced environmental footprint. Axens global offer is based on highly trained human resources, modern production facilities and an extended global network for industrial, technical supports & commercial services. Axens is an IFP Group company.

Press Contact:

Corinne GARRIGA

Head of Axens Group Communications

corinne.garriga@axens.net

Tel.: +33 1 47 14 25 14

Mob.: +33 6 73 85 84 02