Stay Ahead

Upcoming Events

-

Conference

New Orleans, LA - Central Standard Time

3 Days

AFPM Annual Meeting 2026

The AFPM Annual Meeting will be held in New Orleans, LA on March 15 - 17, 2026 at the Hyatt Regency New Orleans. The AFPM Annual Meeting is the world's premier refining meeting, assembling key executives, decision-makers, and technical experts from refining businesses, technology providers, contracting and consulting firms, and equipment manufacturers around the world.

Oil Refining

Energy Efficiency

Benzene Hydrogenation

C₄ Isomerization / Alkylation / Olefins Hydrogenation

C₅-C₆ Isomerization

Catalytic Cracking

Catalytic Reforming

Diesel Hydrotreating

Etherification

FCC Naphtha Hydrotreating

FCC Naphtha Sweetening

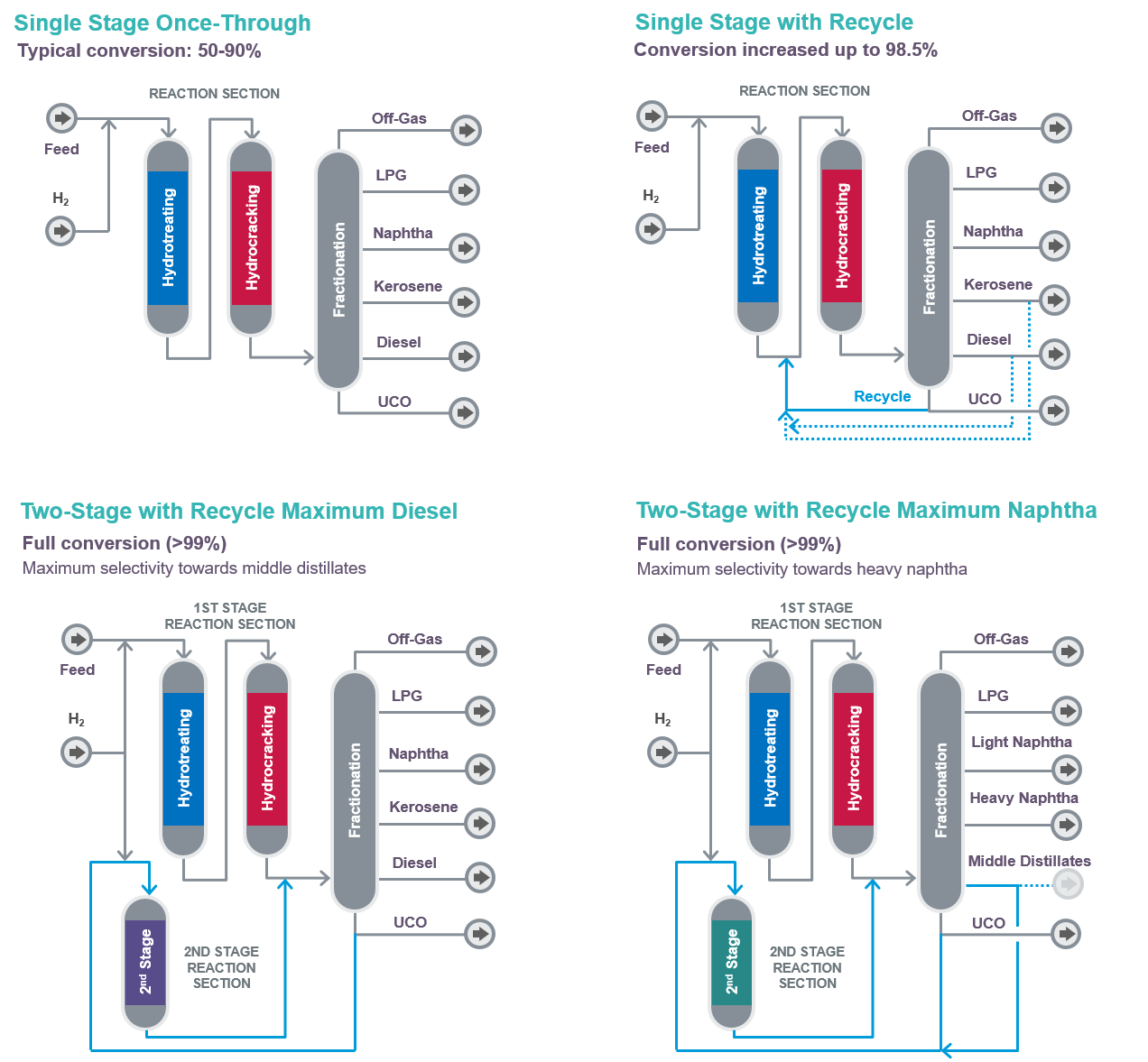

High-conversion Hydrocracking

Kerosene Sweetening / Hydrotreating

LPG Sweetening & Olefins Recovery

Lube Plant

Naphtha Treatment

Oligomerization

Residue Hydroconversion & Hydroprocessing

Thermal Process

VGO Hydrotreating (CFHT) / Mild Hydrocracking

Solvent Deasphalting (SDA)

Digital Services & Applications

Catalysts, Adsorbents, Gradings

Energy Efficiency

Equipment Supply

Furnaces & Waste Heat Recovery

Process Technologies

Technical Support & Performance Management

Training

Unit Revamps & Retrofits

Axens Americas

Chloride Removal Adsorbent

Drying Series Adsorbent

Fluoride Removal on LPG & Alkylate Adsorbent

Mercury Removal Adsorbent

Paraffin Separation Adsorbent

Sulfur Removal for Oil, Gas & Petrochemicals Adsorbent

+36

Explore some

Resources

Technical article

Technical Article - Guiding the crude-to-chemicals complex towards a net-zero future

Technical article

Technical Article - Transforming a refinery unit into a key component of end-of-life plastic circularity

Insight

Maximizing the Production and the Transformation of Aromatics

Insight

Targeting the Highly Coveted Olefins

Insight

Maximizing the Production and the Transformation of Aromatics

Insight

Targeting the Highly Coveted Olefins

Insight

Two Conversion Routes to Maximize the Economic Returns of a Crude-to-Chemicals Project

Insight

Recommended Process Routes for Maximized Oil Conversion to Aromatics and Olefins

Whitepaper

White Paper - Crude-to-Chemicals

Technical article

Technical Article - Guiding the crude-to-chemicals complex towards a net-zero future

Technical article

Technical Article - Transforming a refinery unit into a key component of end-of-life plastic circularity

Technical article

Technical Article - Upgrade Vacuum Residues And Other Hard-to-Convert Heavy Ends To Get More ULSD Through Hydrocracking Solutions

Technical article

Technical Article - Technology Advances Enable Crude To Chemicals Projects

Press release

Successful startup of Axens’ Residue Hydrocracking Unit and High Conversion Hydrocracking Unit at Shenghong’s Integrated Refinery Axens 渣油加氢裂化及高转化率加氢裂化装置在盛虹炼化一体化项目中 成功投产

Press release

Fuhaichuang Petrochemical Selects Axens Ebullated-Bed Residue Hydrocracking Technology (H-Oil®) to Boost the Profitability of its Assets

Press release

Successful operation of Axens’ units and digitalization at the ERC refinery

Press release

Axens’ recent Successes in Hydrocracking

TO CONTACT US

Please fill in the contact form below