Axens’ large technology portfolio includes all the processing steps to produce Group III lube base oils from Vacuum Gasoil (VGO) or Deasphalted Oil (DAO) feedstocks. For this purpose, a combination of hydrocracking (HyK™) and hydrodewaxing (HyDeWax™) technologies is the best choice.

Besides base lube oil technologies, Axens also offers wax hydrotreatment, white oils hydrotreatment technologies allowing our customer to produce different special oils including:

- Feed-grade wax

- Technical grade white oils

- Medical white oils

Select an application

The target of Axens Solutions' Hydrorefining technology is the production of a wide choice of suitable lubricant base stocks from a variety of crude sources. Very similar to the hydrocracking process regarding operating conditions, it uses a special amorphous catalyst having a dual function (hydrotreating and cracking).

The production of lube oils with Viscosity Index (VI) values between 95 and 145 is associated with a conversion to lighter fractions between 20 and 60 wt%.

Process Technologies

Catalysts & Grading Materials

Furnaces & Heat Recovery

Consulting, Supply & Support

Process Technologies

Catalysts & Grading Materials

Furnaces & Heat Recovery

Consulting, Supply & Support

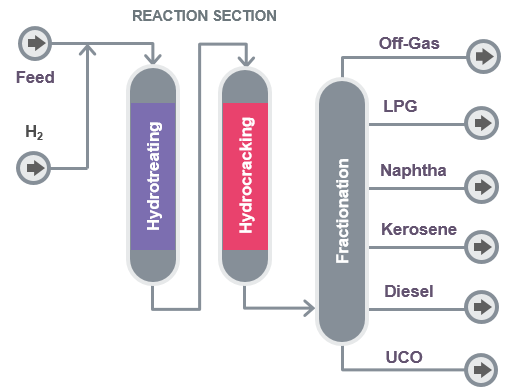

Axens Solutions' HyDeWax™ technology allows the production of high-quality Group III Lube base oils from Unconverted Oil (UCO) from Hydrocracker or from Hydrorefined Vacuum Gasoil (VGO)/Deasphalted Oil (DAO) feedstocks or from 100% Wax feed. The latest combination of hydro-isomerisation and hydrofinishing catalysts will ensure excellent yields and optimum lube quality and stability.

Process Technologies

Catalysts & Grading Materials

Furnaces & Heat Recovery

Consulting, Supply & Support

In order to produce white oils from the existing base oils of the refinery, it is necessary to completely hydrogenate aromatic structures into naphthenic ones.

Process Technologies

Catalysts & Grading Materials

Furnaces & Heat Recovery

Consulting, Supply & Support

Waxes coming from Deoiling need a final hydrotreatment to be used in food applications.

Process Technologies

Catalysts & Grading Materials

Furnaces & Heat Recovery

Consulting, Supply & Support

TO CONTACT US

Please fill in the contact form below