Claus

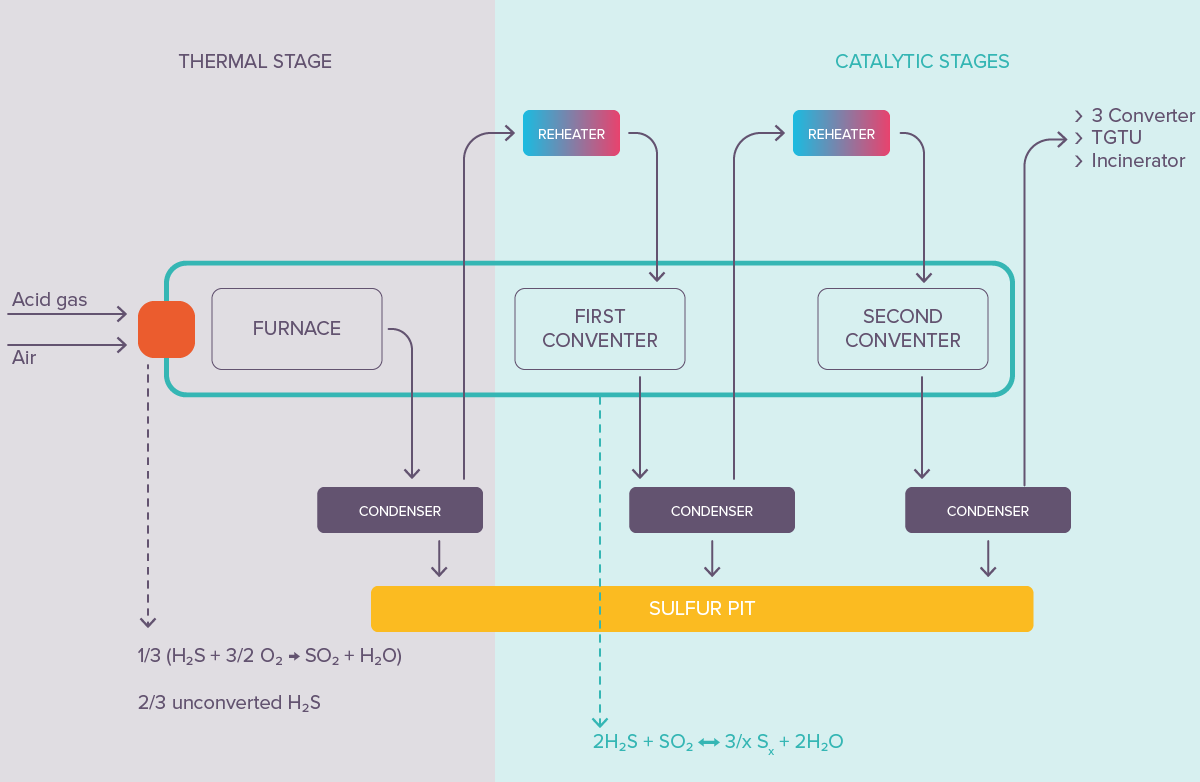

The Claus conventional process allows a sulfur recovery between 95 and 98% by converting H2S present in feed gas streams and recover it as elemental liquid Sulfur. The process is based on the Claus reaction that is composed of two steps, a first thermal stage and a second catalytic stage.

The thermal stage, carried out in the Reaction Furnace, consists in the partial oxidation of H2S to generate Sulfur dioxide (SO2), which will then react with the remaining hydrogen sulfide (H2S) to produce Sulfur in the catalytic stages.

Alumina is the main catalyst used in the Claus process, where the formation of sulfur occurs at the surface of heterogeneous (solid) catalysts. In addition, TiO2 based catalyst is largely used in the bottom of the first Claus reactor to better convert COS and CS2 and further reduce sulfur emissions out of stack. The most suitable catalyst configuration to match the required performances and Catalyst Life Span is selected from Axens large SRU Catalyst Portfolio, on a case by case basis.

More than 60 years of expertise and know how in Claus process

with single train capacity from a few TS/d up to 2,200 TS/d

Most widely recognized

Claus catalysts on the market

Large experience on Claus unit operation and troubleshooting

thanks to several industrial feedbacks

Related Offer