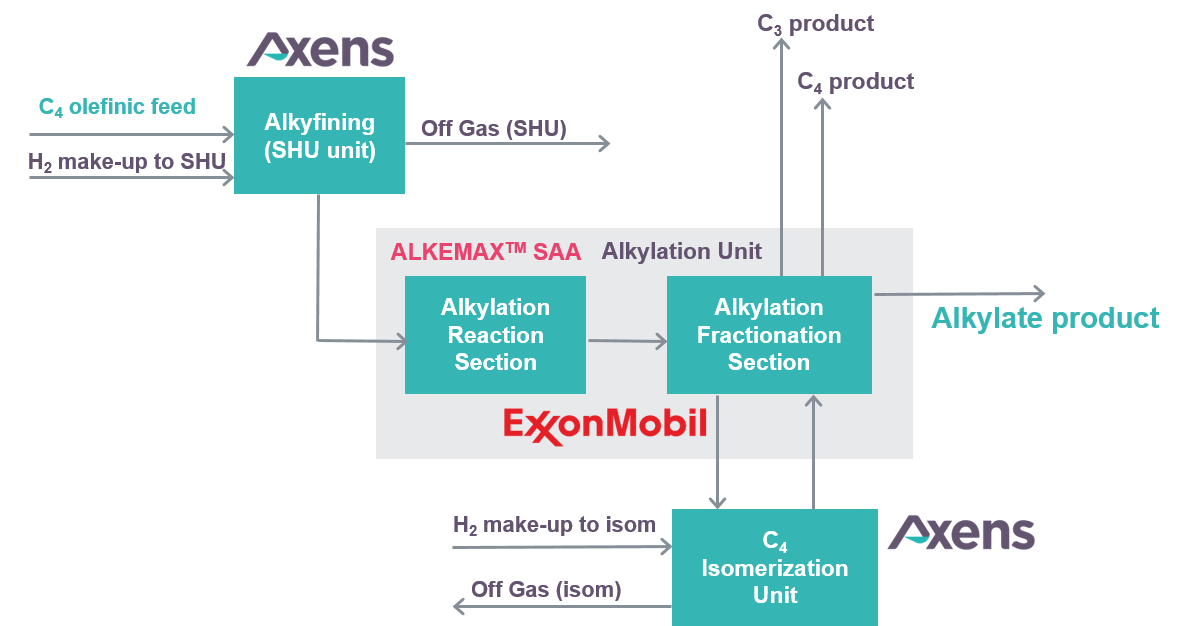

In March 2019, ExxonMobil Catalysts and Licensing LLC (ExxonMobil) and Axens signed an alliance agreement for the sublicense of ExxonMobil’s Sulfuric Acid Alkylation technology. Thanks to the ALKEMAX™ alliance, Axens and ExxonMobil will market and deliver all technologies associated within a refinery alkylation block, which includes Axens feed preparation, or Alkyfining, n-Butane Isomerization, and ExxonMobil’s Sulfuric Acid Alkylation.

Select an application

Butadiene makes unwanted high boiling oligomers often called sludge or ASO (Acid Soluble Oils). When ASO is removed, significant amounts of alkylation catalyst (HF or H2SO4) leave with it. ASO is hazardous and difficult to dispose of properly; a high ASO amount means yield and catalyst loss. Alkyfining® solves these problems producing some very attractive results.

Alkyfining® is the market leader for upgrading alkylation plant feeds. By converting butadiene to butenes (for higher alkylate octane) Alkyfining® greatly enhances alkylation plant performance.

With respective Alkyfining® market shares of 70% and 95% of the HF and H2SO4 alkylation feed pretreatment plants, Axens is the world’s leading player in alkylation plant feed pretreatment.

Process Technologies

Catalysts & Grading Materials

Adsorbents

Consulting, Supply & Support

Alkylate is a superior component that increases the octane of premium motor fuels. ExxonMobil’s proven Sulfuric Acid Alkylation (SAA) technology reacts light olefins with isobutane to form high value alkylate for gasoline blending.

ALKEMAX™ SAA technology is based on ExxonMobil’s 60+ years of design and operational experience, and is used in some of the world’s largest refineries. ExxonMobil and Axens have signed an alliance agreement for the sublicense of ExxonMobil’s Sulfuric Acid Alkylation technology. This alliance leverages collective expertise by providing a streamlined solution and proven technologies to optimize high-octane fuels production.

Process Technologies

Consulting, Supply & Support

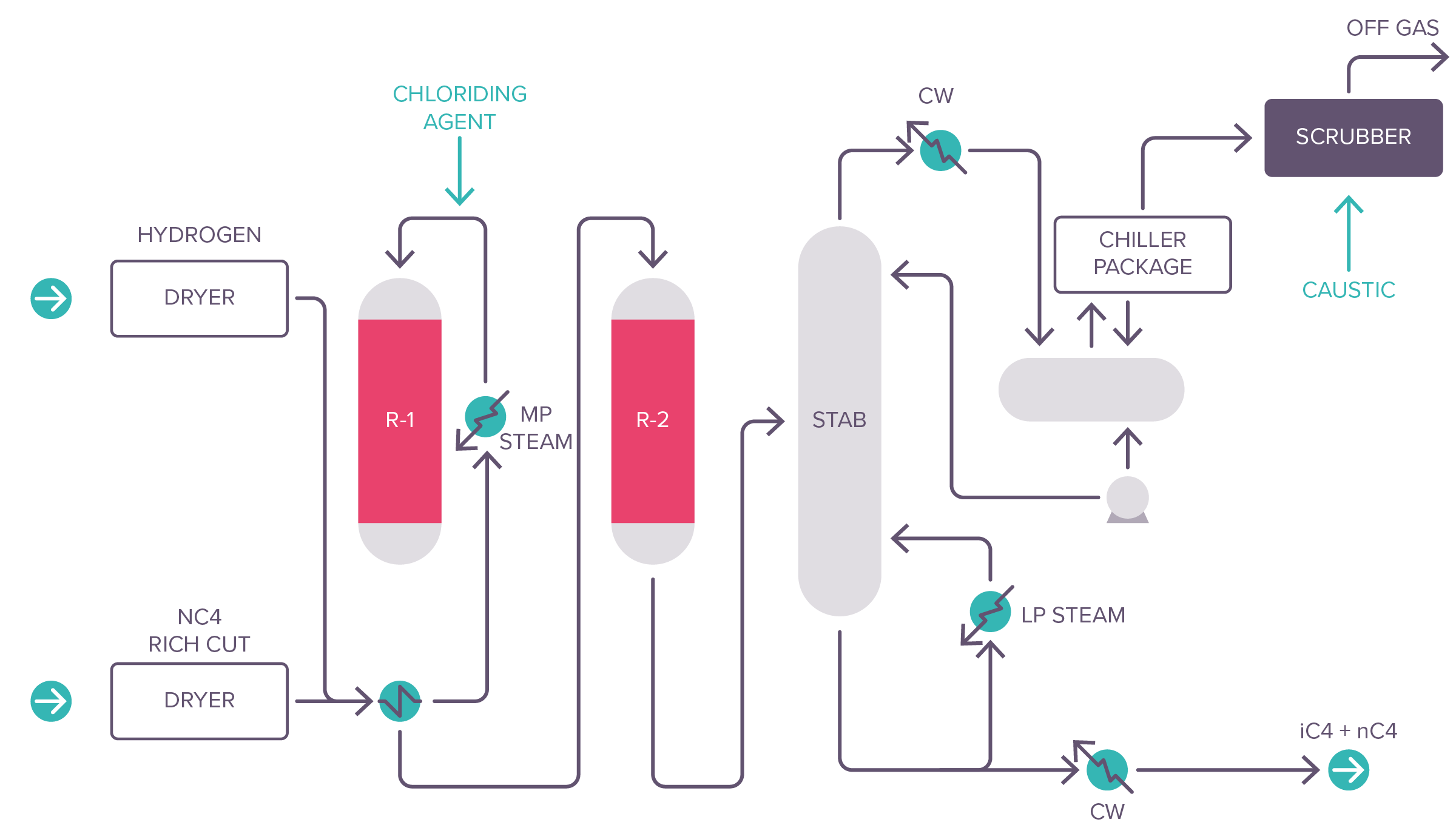

C4 isomerization is a process allowing to restore the thermodynamic equilibrium (iC4/nC4) in a C4 paraffinic cut. Integrated with an alkylation unit, this process allows to provide the missing isobutane to the alkylation reaction.

Process Technologies

Catalysts & Grading Materials

Adsorbents

Consulting, Supply & Support

In an HF Alkylation unit, purified light olefins (C3 and C4) from an FCC unit are combined with isobutane to generate alkylate, a high octane product that can be blended into the gasoline pool.

Adsorbents

Consulting, Supply & Support

The hydrogenation technology is aimed at producing high purity solvent and is operated at extremely high severity to meet tight aromatics specifications as low as 10 ppm in the hydrogenated product while achieving complete diolefin and olefin saturation.

Consulting, Supply & Support

Upcoming Events

Resources

Case Study - Refining to olefins production

Axens Selene™ Selective Hydrogenation Catalysts new family

New reference in Asia for LD 153 Axens’ selective hydrogenation catalyst for C2 front-end application

Axens’ Technologies for Petron Corporation in the Philippines

TO CONTACT US

Please fill in the contact form below