Select an application

Axens can offer a large range of simple, robust and flexible processes to address the market demand:

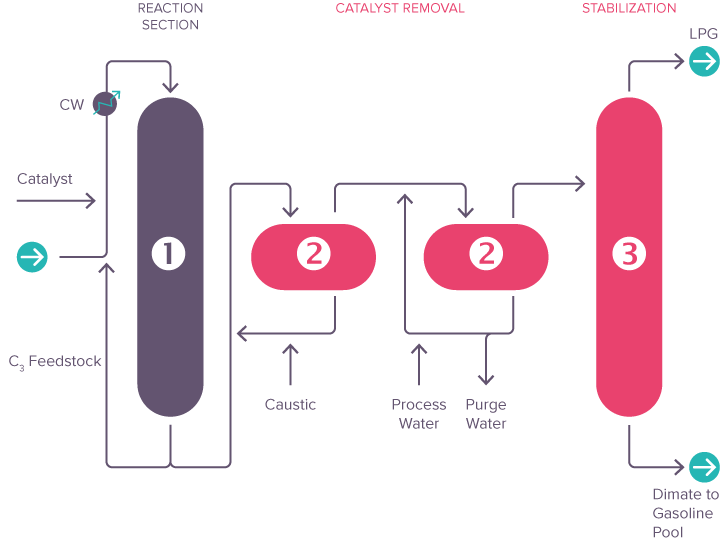

- Polynaphtha™, Selectopol™ and PolyFuel® are Axens technologies which oligomerize olefins contained in the light cracked cut into higher value olefinic cuts which can be used as high octane gasoline or high cold properties kerosene or diesel fraction.

- FlexEne™ is an innovative combination of two well-proven technologies: Fluidized catalytic cracking (FCC) and Oligomerization to expand the capabilities of the FCC process which is the main refinery conversion unit traditionally oriented to maximize gasoline and at times propylene production.

Process Technologies

Catalysts & Grading Materials

Adsorbents

Consulting, Supply & Support

Process Technologies

Catalysts & Grading Materials

Adsorbents

Consulting, Supply & Support

Stay Ahead

Upcoming Events

-

Conference

New Orleans, LA - Central Standard Time

3 Days

AFPM Annual Meeting 2026

The AFPM Annual Meeting will be held in New Orleans, LA on March 15 - 17, 2026 at the Hyatt Regency New Orleans. The AFPM Annual Meeting is the world's premier refining meeting, assembling key executives, decision-makers, and technical experts from refining businesses, technology providers, contracting and consulting firms, and equipment manufacturers around the world.

Oil Refining

Energy Efficiency

Benzene Hydrogenation

C₄ Isomerization / Alkylation / Olefins Hydrogenation

C₅-C₆ Isomerization

Catalytic Cracking

Catalytic Reforming

Diesel Hydrotreating

Etherification

FCC Naphtha Hydrotreating

FCC Naphtha Sweetening

High-conversion Hydrocracking

Kerosene Sweetening / Hydrotreating

LPG Sweetening & Olefins Recovery

Lube Plant

Naphtha Treatment

Oligomerization

Residue Hydroconversion & Hydroprocessing

Thermal Process

VGO Hydrotreating (CFHT) / Mild Hydrocracking

Solvent Deasphalting (SDA)

Digital Services & Applications

Catalysts, Adsorbents, Gradings

Energy Efficiency

Equipment Supply

Furnaces & Waste Heat Recovery

Process Technologies

Technical Support & Performance Management

Training

Unit Revamps & Retrofits

Axens Americas

Chloride Removal Adsorbent

Drying Series Adsorbent

Fluoride Removal on LPG & Alkylate Adsorbent

Mercury Removal Adsorbent

Paraffin Separation Adsorbent

Sulfur Removal for Oil, Gas & Petrochemicals Adsorbent

+36

-

Conference

Houston, Texas - Central Standard Time

5 Days

World Petrochemical Conference (WPC) 2026

The World Petrochemical Conference (WPC) is held on March 23-27, 2026 in Houston, TX. The WPC stands as the longest-running and most esteemed event in the petrochemical industry, boasting a legacy that extends over 40 years.

Petrochemicals

Aromatics Extraction

Benzene Production

C₄ Fractionation

C₄ Upgrading

C₅ Skeletal Isomerization

Catalytic Cracking

Catalytic Reforming

Cyclohexane Production

EDC Cracking

Olefins Purification

Olefins Removal

Olefins Selective Hydrogenation

Oligomerization

Paraxylene Purification & Production

Phenol Production

Xylenes Production

Xylenes Isomerization

Total Hydrogenation

Styrene Production

Steamcracker

Process Technologies

Axens Americas

Arsine Removal Adsorbent

Chloride Removal Adsorbent

Drying Series Adsorbent

Mercury Removal Adsorbent

Purification Series Adsorbent

Sulfur Removal for Oil, Gas & Petrochemicals Adsorbent

Americas

+29

Explore some

Resources

Technical article

Technical Article - Maximize Refinery Profitability with Novel RFCC Technologies

Whitepaper

White Paper - Crude-to-Chemicals

Technical article

Technical Article - Tackling the Gasoline / Middle Distillate Imbalance

Technical article

Technical Article - Using Technology to Increase Middle Distillate Production

Whitepaper

White Paper - Crude-to-Chemicals

Technical article

Technical Article - Maximize Refinery Profitability with Novel RFCC Technologies

Technical article

Technical Article - Using Technology to Increase Middle Distillate Production

Technical article

Technical Article - Tackling the Gasoline / Middle Distillate Imbalance

Technical article

Technical Article - Shale Gas Drives New Opportunities For US Downstream

FAQ

We are aiming to boost our FCC propylene output. What recent developments would you recommend?

Press release

Aramco And Sumitomo Chemical Sign Licensing Agreement For Axens’ AFA Technology

Press release

Gevo Selects Polynaphtha™ Technology and Engineering from Axens

Press release

Arcanum Infrastructure successfully startup Axens AlphaButol® technology at its Raven Butene-1 facility in Houston, TX

Press release

Axens’ Technologies for HPCL Rajasthan Refinery in India

TO CONTACT US

Please fill in the contact form below