Select an application

The chemicals, road transport and aviation sectors are facing multiple challenges: reducing their dependence on petroleum resources with cost-competitive solutions and addressing today's environmental concerns - sustainability and lower greenhouse gas emissions.

Renewable lipids based fuels are an important tool to address issues raised by policies put in place in order to reduce the dependence of the transportation sector on fossil fuels and to promote the development of sustainable and low-carbon fuels.

Process Technologies

Catalysts & Grading Materials

Adsorbents

Furnaces & Heat Recovery

Consulting, Supply & Support

The chemicals, road transport and aviation sectors are facing multiple challenges: reducing their dependence on petroleum resources and addressing today’s environmental concerns - sustainability and greenhouse gas emissions reduction.

Axens addresses these challenges through the offer of several technologies able to produce renewable fuels and bio-based chemicals from a wide variety of biomass feedstocks: oils & fats (renewable lipids) as well as lignocellulosic biomass (agricultural and forestry residues, energy crops, woody wastes etc.).

BioTfueL® technology suite combines in a complete and fully integrated Biomass To Liquids (BTL) chain proven technologies from key industrial partners; including Axens Gasel® technology for Fischer-Tropsch synthesis and upgrading.

Process Technologies

Adsorbents

Furnaces & Heat Recovery

Consulting, Supply & Support

The chemicals, road transport and aviation sectors are facing multiple challenges: reducing their dependence on petroleum resources and addressing today’s environmental concerns - sustainability and greenhouse gas emissions reduction.

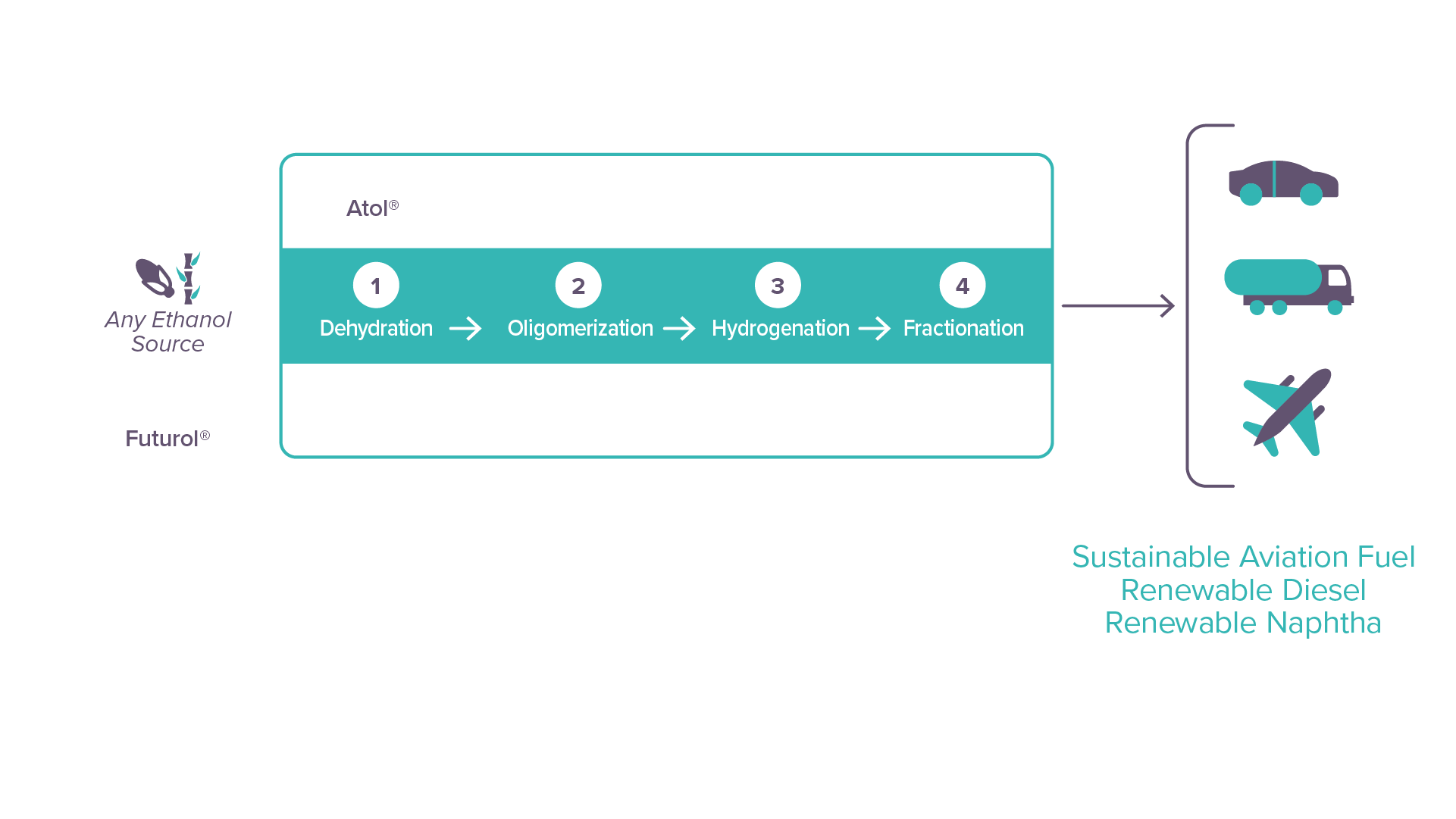

Axens addresses these challenges through the offer of several technologies able to produce renewable fuels and bio-based chemicals from a wide variety of biomass feedstocks: oils & fats (renewable lipids); lignocellulosic biomass (agricultural and forestry residues, energy crops, woody wastes) and also 1G and 2G ethanol and bio-olefins.

The Jetanol® suite is a pathway for producing Sustainable Aviation Fuels by converting ethanol or iso-butanol.

Process Technologies

Catalysts & Grading Materials

Adsorbents

Consulting, Supply & Support

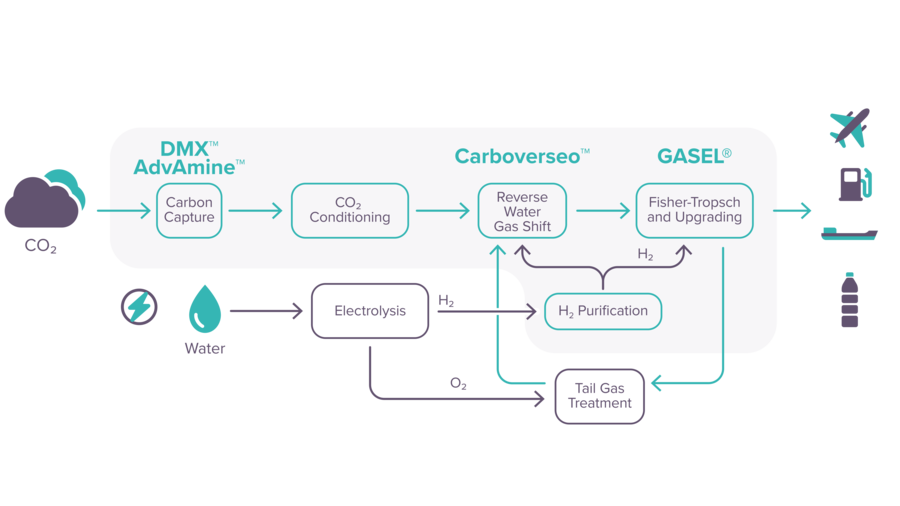

The decarbonization of industries that emit large amounts of CO₂, such as cement, steel, incinerators, pulp and paper, biomass boilers, refineries, and chemistry, can be addressed by capturing and converting the CO₂ into renewable or low-carbon fuels.

This process relies heavily on low-carbon electricity (used to produce hydrogen), which is then mixed with CO₂.

As a result, the final life cycle analysis of these fuels shows a lower carbon footprint. This approach offers a solution for decarbonizing the transportation sector, including maritime, aviation, and both light and heavy-duty vehicles.

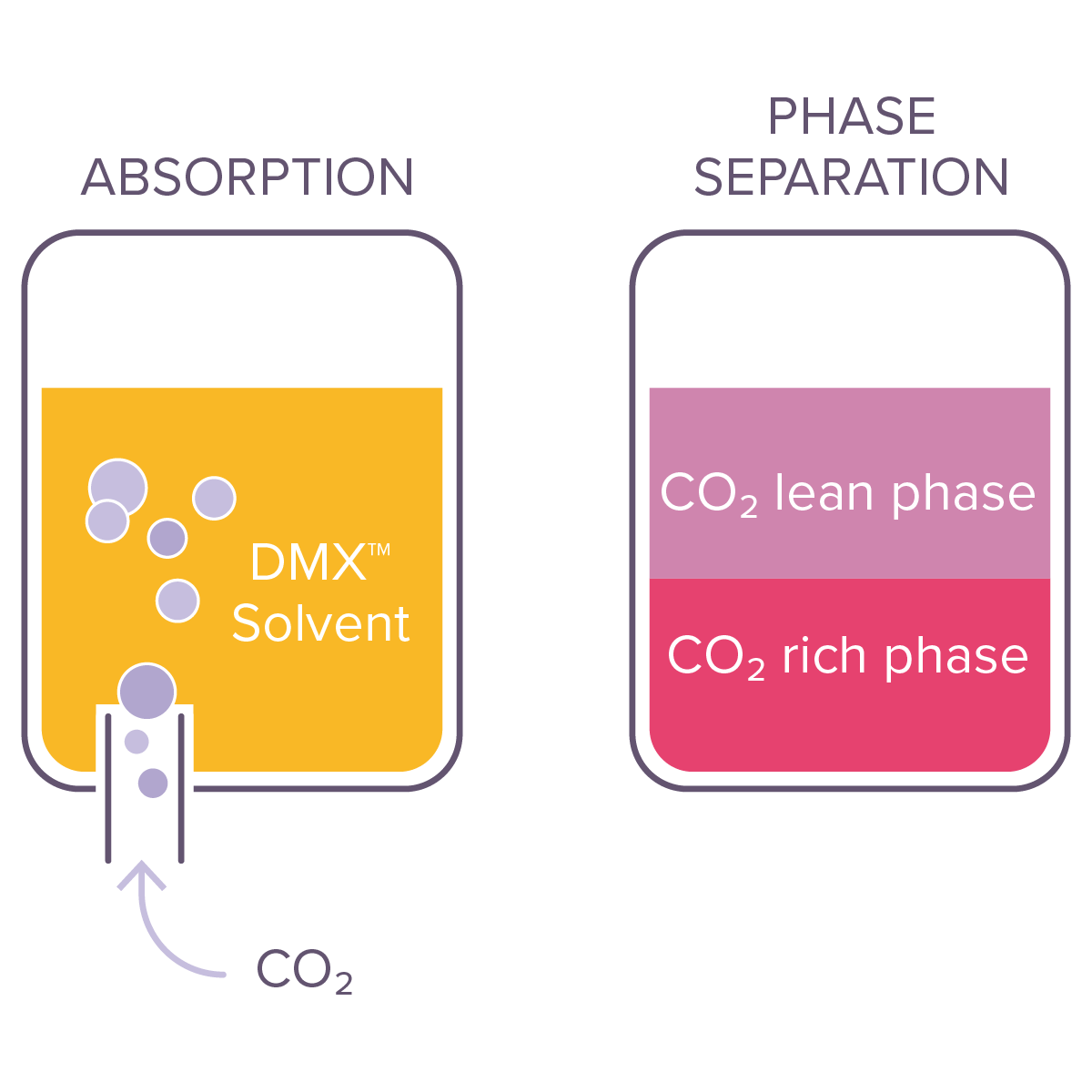

Axens offers a comprehensive range of technologies, including Carbon Capture (DMX™, Advamine™), Reverse Water Gas Shift (Carboverseo™), CO₂ conditioning, H₂ purification, Fischer Tropsch, and Upgrading (Gasel®), to convert CO₂ into renewable/low-carbon fuels at low operating cost.

Furthermore, the more stringent specifications are met with a diverse range of products allowing the purification of CO₂, Syngas and H₂. The RWGS and Fischer Tropsch catalysts are protected against poisoning and deactivation.

The bankability of your project is guaranteed through a single point of contact, strong research and development support, and integrated guarantees.

-

Integrated and innovative technologies and products (catalyst & adsorbents) to enhance the profitability of your low-carbon projects

-

With a single point of contact, Axens takes full responsibility for the project, improving its bankability.

-

From conceptualization and feasibility studies to basic engineering, start-up, and operation, Axens is the ideal partner to support your decarbonization projects.

Process Technologies

Catalysts & Grading Materials

Adsorbents

Consulting, Supply & Support

Upcoming Events

Technical Article - Vegan technology: low-carbon solution for renewable diesel and SAF

Webinar - Strategic Pathways to Secure SAF Production Technologies

Technical Article - SAF: Finding scalable solutions

Technical Article - Connecting the Dots to Bankability with Low-Carbon Bio-Hubs for Sustainable Fuels and Chemicals

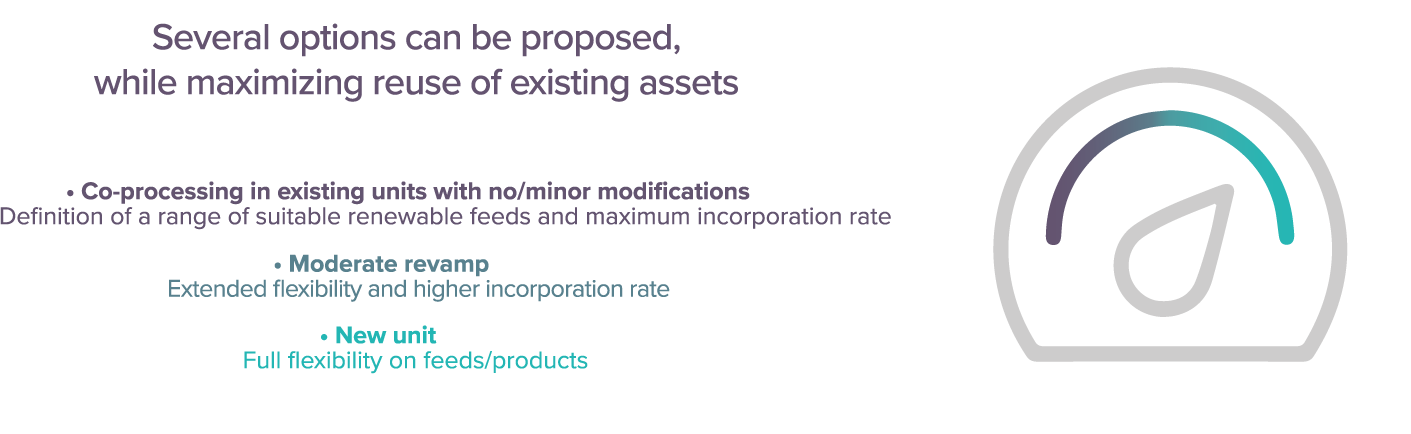

Case Study - Producing Renewable Liquid Products From Different Lipid Feedstocks Through a Revamp

Read moreCase Study - Feasibility Study Of A Standalone Biorefinery For MGH Based On Axens’ Biofuel Technologies Portfolio Vegan® And Futurol™

Read moreTechnical Article - Vegan technology: low-carbon solution for renewable diesel and SAF

Technical Article - SAF: Finding scalable solutions

Technical Article - Connecting the Dots to Bankability with Low-Carbon Bio-Hubs for Sustainable Fuels and Chemicals

Technical Article - Fueling the future of aviation – the role of low-carbon hydrogen in SAF production

How can the refining industry supply the aviation industry’s growing demand for sustainable aviation fuel (SAF)? What are the most efficient pathways?

What’s the range of drop-in fuels we could potentially produce from biofeedstocks (lipids) with an appropriate process line-up?

Advancing SAF in Asia: Axens Becomes a Gold Member of ASAFA

Axens tapped for 3 new Vegan® licenses by Galp, LOKEN and SAFCO Ventures, for SAF and Renewable Diesel Production

SAF: KazMunayGaz and Axens extend collaboration

E-fuels: Axens, Paul Wurth (SMS group) and IFPEN sign an agreement for the co-development of the Reverse Water Gas Shift technology

Webinar - Strategic Pathways to Secure SAF Production Technologies

Read more

Video - Axens 700 Series - Catalysts Dedicated to the Hydrotreatment of Pyrolysis Oils and Renewable Fuels

Read moreVideo - E-BioTfueL- A Versatile and Integrated Solution Combining the Best of Biomass To Liquids and E-fuels Worlds

Read moreGet in Touch with Us!

Have questions about our offers and solutions or need assistance? The Axens team is here to help. Just a message away!