RAM™

RAM™ processes are proposed for the many large gas and oil reservoirs containing concentrations of arsenic and mercury as low as ppb (parts per billion - 109), as well as contaminants introduced via transport and storage operations that can damage equipment, poison catalysts and generate environmental problems.

The RAM™ processes provide the ultimate solution, transforming the condensate's value from negative to positive. Considering that most of the production cost is in the feedstock alone and that adding a simple process has minimum impact on the overall investment schedule, the financial leverage afforded by this process is considerable.

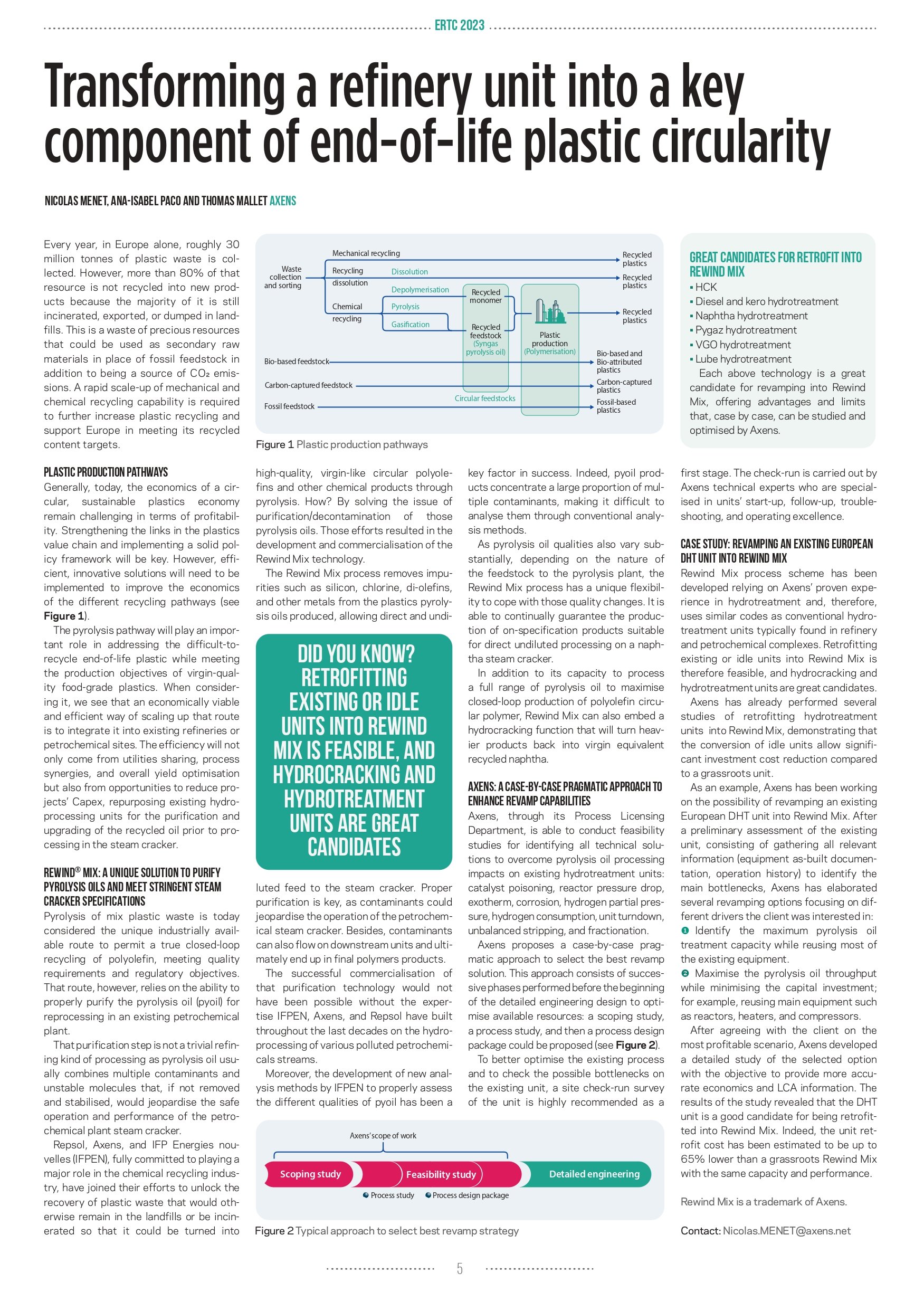

Depending on the types of contaminants present in the feed, the different options of the RAM™ process are as follow:

- RAM™ II – One step

- RAM™ II – Two steps

- RAM™ III

16 RAM™ units

have been licensed worldwide

Excellent

industrial results

Outstanding

return on investment